The changes in temperature differences throughout the four seasons and the surrounding environmental temperature pose a challenge and impact on the performance and reliability of connectors in their environment. Therefore, high and low temperature resistance is also an important technical indicator for evaluating industrial connectors. So what is the high and low temperature resistance performance of connectors? How to improve the high and low temperature resistance of connectors?

How can connectors achieve stronger extreme temperature resistance?

01. What is the high and low temperature resistance performance of connectors?

The high and low temperature resistance of a connector refers to its ability to maintain stable functionality and performance in both high and low temperature environments. Excessive high temperatures generally lead to a decrease in connector strength or even softening, while excessively low temperatures can increase the brittleness of the connector and make it prone to brittle fracture. Therefore, any connector has a range of high and low temperatures for normal operation. A wider range of high and low temperatures can adapt to more harsh temperature environments, and industrial connectors typically have a wider range of ambient temperatures.

02. How can connectors achieve stronger resistance to high and low temperatures?

1. Choose high-quality materials that are resistant to high and low temperatures.

Choose materials that are more resistant to high and low temperatures, and metals can be made of materials such as stainless steel, copper alloy, zinc alloy, etc; Plastic can be used for outdoor engineering, silicone rubber, etc.

2. Optimize structural design.

For example, arranging the pins and solder joints of the connector reasonably to reduce temperature stress; Optimize the structural design of connectors to improve their heat dissipation performance.

3. Better product processing quality.

Better processing quality will result in less stress concentration, and areas with defects are most likely to become the locations with the highest temperature stress, leading to damage.

Recommended Product BD Series: Red Dot Award Masterpiece, Industrial Aesthetics Model

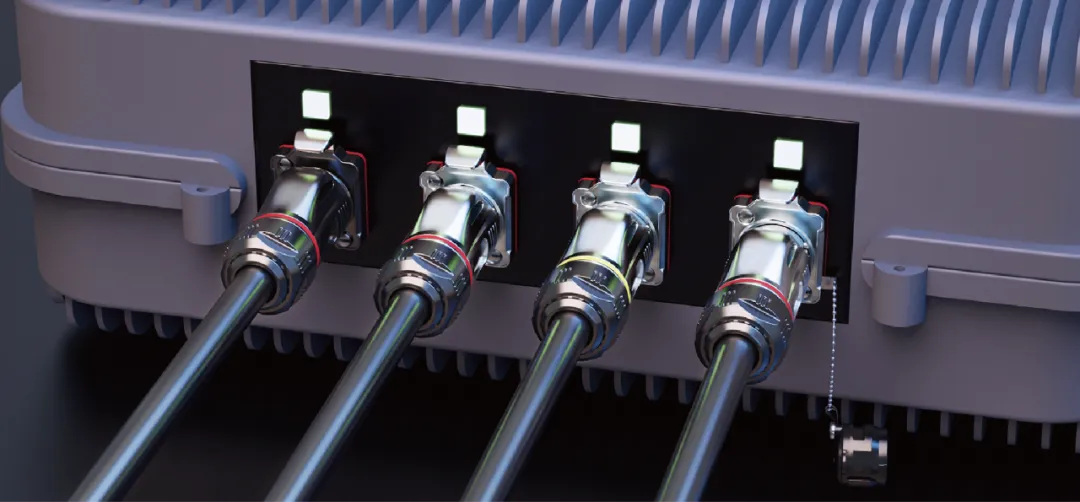

The BD series industrial connectors are a masterpiece that has won the German Red Dot Design Award and the Shenzhen Enterprise Innovation Record Award. It adopts a unique streamlined body design combined with a hollow curved back top, which can be regarded as a breakthrough forward-looking innovation in the industry, truly achieving the perfect integration of industrial products and artistic aesthetics.

The product features include power supply, signal (PIN pin type, RJ45, fiber optic), and data (USB2.0, USB3.0, HDMI) connections, which can meet the multiple technical requirements of different scenarios and devices for connections.

BD series: resistant to high and low temperatures, how to achieve it?

1. Select alloys or outdoor engineering plastic materials that are more resistant to high and low temperatures

2. Reasonable layout, optimized design, more prominent heat dissipation and heat resistance

3. Precision machining, detail control, defect free, stronger resistance to temperature stress

4. Through testing in high and low temperature environments, the following wide temperature environment requirements are met

The performance of this product in high and low temperature resistance is very awesome, and the adaptive ambient temperature is -40 ℃~+85 ℃ (metal version) and -25 ℃~+85 ℃ (plastic version), which is a good choice for professional connection schemes under severe temperature environment.

One of the recommended industries: LED display screens

LED display screens are widely used display and display hardware products, with a significant proportion in outdoor applications. There are many environmental challenges to face, such as harsh temperature environments. Therefore, whether it can adapt to the test of high and low temperature environments and ensure the normal operation of electrical connections is a necessary technical requirement and standard for LED display screens to require connectors.

CNLINKO's BD series industrial connectors are made of high-quality alloys or outdoor engineering plastic materials that are more resistant to high and low temperatures. The internal structure is designed and optimized for better heat dissipation and heat resistance. They are also processed with precision technology, making them more resistant to high temperatures and severe cold. It can ensure continuous and reliable connection under high temperature or severe cold conditions such as outdoors and indoors.

Of course, in addition to its high and low temperature resistance, the BD series also performs excellently in IP68 waterproofing, corrosion resistance, vibration and impact resistance, and stable connection, and is widely recognized and accepted by LED display screen manufacturers.

About CNLINKO

CNLINKO is a national high-tech enterprise and a specialized "little giant" enterprise specializing in the research and production of industrial connectors. We adhere to original research and development and independent brand building, and our products are well received by users in more than 170 countries and regions worldwide.

CNLINKO is one of the drafters of industry standards and has participated in the drafting of the standard "Plug, socket, and marine coupler for high-voltage shore power connection systems (HVSC systems) Part 1: General requirements". This standard belongs to the shipbuilding industry standard and has strict requirements for waterproofing.